Electroplating Advisory Services

Advint Incorporated provides electroplating advisory services designed to advance our clients’ businesses with a focus on quality, effectiveness, and operational excellence.

We review each client’s process performance and capability methods and seek to discern their wants and expectations. Our clients lead the industry and achieve a true electroplating capability with improved quality, timely delivery, and customer and employee satisfaction in the long term. We comply with and aim to maintain high Corporate Social Responsibility (CSR) standards.

Advint’s Approach to Machine Learning in Surface Finishing

At Advint, we focus on blending science, mathematics, and technology to support surface finishing clients in exploring data-driven solutions. Our services introduce machine learning (ML) applications designed to enhance process understanding and operational efficiency to premium clients.

Machine learning offers a way to integrate and analyze complex datasets, uncovering insights that might not be immediately visible with traditional tools. By incorporating predictive analysis and algorithmic approaches, businesses can explore data more thoroughly and identify opportunities for process improvement.

Advint’s goal is to support clients in adopting ML methods at a comfortable pace, ensuring these technologies complement their current practices. We provide practical guidance for selecting algorithms that align with specific needs while considering scalability and ease of use.

While machine learning holds significant potential, we understand that its application is a step-by-step process. Our approach emphasizes realistic and incremental progress, helping industries make informed decisions about integrating new technologies.

Advint remains committed to assisting clients in advancing their capabilities through thoughtful application of ML, SPC, PLC, and related tools. For surface finishing professionals seeking to explore these possibilities, we aim to offer reliable guidance every step of the way.

Elevating Industries with Electroplating Advisory Services

Advint has a strong history of helping businesses in industries like aerospace, automotive, and manufacturing improve their electroplating processes. Our advisory services focus on enhancing product performance, ensuring compliance with standards, and optimizing efficiency. Whether it’s improving corrosion resistance, achieving uniform coatings, or meeting strict material requirements, we deliver practical, impactful solutions.

Organizations have trusted Advint to set up efficient plating lines, adopt advanced technologies, and implement sustainable practices. Through our guidance, clients have improved operations by streamlining production, reducing waste, and staying environmentally compliant.

With Advint, you gain a dedicated partner focused on your success. Our team provides personalized consultations, offering expertise in process optimization, rectifier selection, chemical usage, and equipment setup. By working with us, you can reduce costs, increase efficiency, and stay competitive.

Advint’s services ensure your electroplating processes are reliable, innovative, and aligned with industry standards.

Contact us to discover how we can help you achieve your goals.

Why Customers Choose Advint Advisory Services

1

Design manual, automatic or state of art electroplating plant or processing line.

2

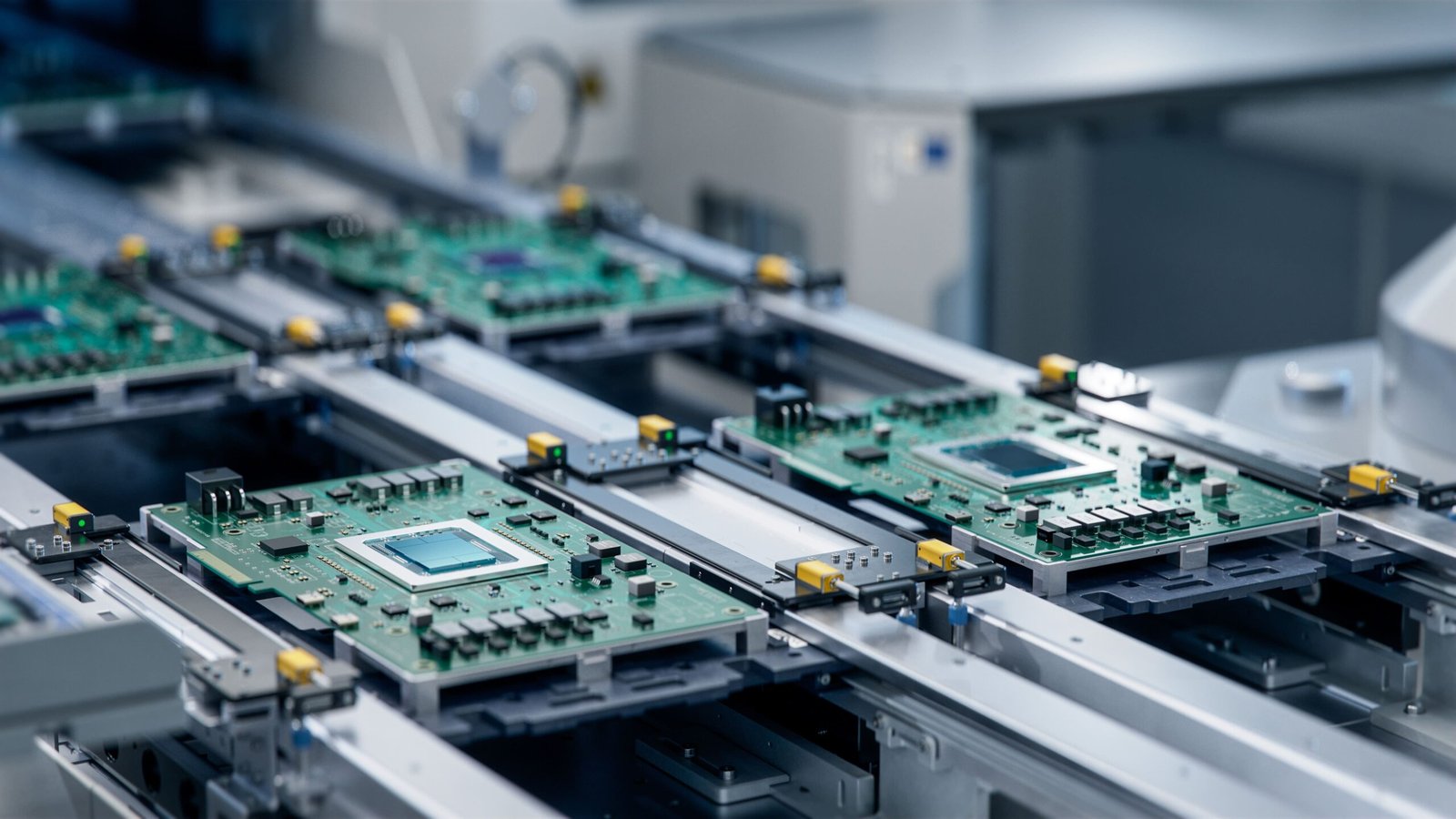

Optimize barrel, rack, reel to reel, plating on plastic (POP), continuous strip plating, and plating on PCB’s.

3

Process optimization and effectiveness

4

Improve lean, statistics, and productivity practises.

5

Research support on REACH alternatives such as trivalent decorative and hard plating, conversion coating and electroless Ni alloy plating.

6

Optimize difficult to plate deposit alloys such as alkaline nickel-zinc, bronze and brass on aerospace and automotive applications.

7

Plating on exotic alloys like high nickel stainless steel alloys, Inconel, titanium and aluminum.

8

Plating indium, tin, palladium and gold on connectors and printed circuit boards using automation lines with programmable logic control (PLC) software.

Advint staff are familiar with the intricacies and nuances involving complex and multi-step processes. Advint’s electroplating advisory services deliver structured, formal, and succinct remedies. We review data, analyze, and submit a corrective action recommendation (CAR) report. Our services are virtual and we meet in person at our client’s facility based on their request.

Adherent to our CSR policy, we offer an option to sign the two-way non-disclosure agreement (NDA) for mutual protection of data and information. This ensures privacy and security of client data.

Advint developed the proprietary Time Change Management (TCM) tool using decades of manufacturing, research, and engineering experience. Our evaluation and recommendations extend to topics such as production and people management, lean, total quality management (TQM), chemistry, electrochemistry, process control, statistical process control (SPC), analyzes, physical characterization, effectiveness, automation and equipment engineering.

Our team has good links with the industry and research institutes. We are expanding and look for fresh business opportunities which meets our codes and values.

We understand each customer’s requirements are different. You may have personnel with advanced skills, or perhaps your process line is complex and requires precise attention. No worries; we listen, adapt to your needs, and guarantee results.

Grab the opportunity and subscribe to find out how your company can benefit like others.

We center our vision on our users to help them master the use of science, mathematics, technology, and management to realize their desired capabilities. We are working to develop a customized management concept based on emotional intelligence for global surface finishing clients.

A breakthrough algorithm and machine learning program for worldwide electroplating applications are in the concluding stages of work.

The drive of Advint is to practise the influence of intentions on the approaches. Our recommendations and emphases begin with intentions to accomplish infinitely valuable outcomes.

Unlike Electroplating consultant who focus on solving problems, Advint’s unique advisory services focusses on cost reduction by working on fundamentals, method, innovation, and critical thinking on quality and delivery attributes..

Elevate Your Electroplating Process with Advint

Since 2018, Advint Incorporated has earned global trust, operating across four business segments in five countries. We offer the expertise to streamline operations, reduce costs, and drive innovation in electroplating processes.

Book a Free Consultation