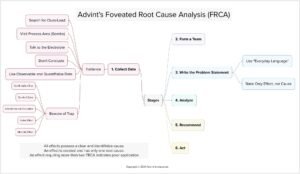

Advint’s Foveated Root Cause Analysis: A Novel Approach

Introduction

Root cause analysis (RCA) stands as a cornerstone process in identifying and rectifying the underlying causes of issues or defects across industries. Despite the widespread use of traditional RCA tools like Fishbone diagram and 5 Why’s analysis, their effectiveness in pinpointing root causes, particularly in addressing chronic or enduring effects within the electroplating industry, has come under scrutiny. This paper introduces Advint’s Foveated Root Cause Analysis (FRCA) tool guide, aiming to present a more efficacious approach to RCA.

The Need for FRCA

While traditional RCA tools possess their strengths, they often prove inadequate in tackling chronic effects persisting over several years. The author of this paper has noted several cases where companies faced difficulty in pinpointing root causes, despite making concerted efforts. Thus, this endeavor represents a culmination of various observations, insights, and studies.

Key Principles of FRCA Single Root Cause:

FRCA operates under the principle that an effect stems from a singular root cause, notwithstanding the presence of numerous sub-causes. This stands in contrast to the common misconception of attributing multiple root causes to a single effect. Distinguishing between a root cause and potential causes is also of significance.

Foveated Approach:

The term “foveated” denotes the focused and concentrated analysis requisite for identifying the root cause. FRCA underscores the importance of scrutinizing evidence and being cognizant of potential traps or biases that might impede the analysis.

Stages of FRCA

Collect Data:

Efficient data collection serves as a linchpin for a successful investigation. FRCA accentuates the significance of compiling clean and pertinent data, recognizing that incomplete or irrelevant data can impede the analysis. One must recognize there is always hidden data, and the role of the facilitator is to expose and present the hidden data and reveal to the team.

Form a Team:

FRCA advocates for the formation of a team comprising approximately five members with diverse technical backgrounds who are directly involved with the effect. To mitigate confirmation bias and potential pitfalls, it is advisable to exclude members who have previously participated in RCA for the same effect. It is prudent to recognize that an effect requiring more than two FRCA indicates poor application.

Write the Problem Statement:

The problem statement should be articulated in plain language, focusing exclusively on the effect and eschewing technical jargon or potential causes. This approach ensures that the analysis remains untainted by preconceived notions or premature conclusions.

Analyze:

FRCA underscores the importance of expeditious analysis, ideally within 48 hours of defect occurrence or detection. This proactive approach heightens the likelihood of identifying the root cause before evidence becomes compromised, obscured, or forgotten. It is pertinent to be systematic in approach, ask only whys, not to discuss, argue or debate the causes.

Recommend:

Based on the identified causes and root cause, FRCA advocates for implementing corrective actions. In a manufacturing setting, it is often imperative to enact multiple measures to mitigate the repercussions of non-conformance.

Act:

The final stage of FRCA entails executing the recommended actions. It is imperative to follow through with the prescribed measures, as shifting priorities in a bustling manufacturing environment can lead to lapses in implementation.

Conclusion

FRCA presents a novel and targeted approach to root cause analysis, addressing the shortcomings of traditional RCA tools in pinpointing root causes for chronic or enduring effects. By espousing a foveated approach, evidence-based analysis, and prompt action, FRCA endeavors to provide a more effective solution for identifying and rectifying the underlying causes of issues or defects in electroplating applications.

Learn More

Copper Electrowinning: Advanced Rectifier Systems and Power Supplies

The captivating prelude above expertly introduces the comprehensive guide, while Advint’s Online Industrial Electroplating training provides an in-depth, thorough explanation that is sure to equip the students with the essential knowledge and skills needed to excel in this field.

Posted By:Venkat Raja

Apr 25, 2024

Tags: