Hydrogen Embrittlement: The Hidden Danger Compromising Metal Strength

In the world of metallurgy and manufacturing, there’s an invisible enemy that can turn the strongest metals brittle and cause catastrophic failures without warning. This nemesis is hydrogen embrittlement, a phenomenon that has kept engineers, metallurgists, and heat treatment specialists on their toes for decades. Today, we’re diving deep into this critical issue that affects industries ranging from aerospace to everyday manufacturing.

What is Hydrogen Embrittlement?

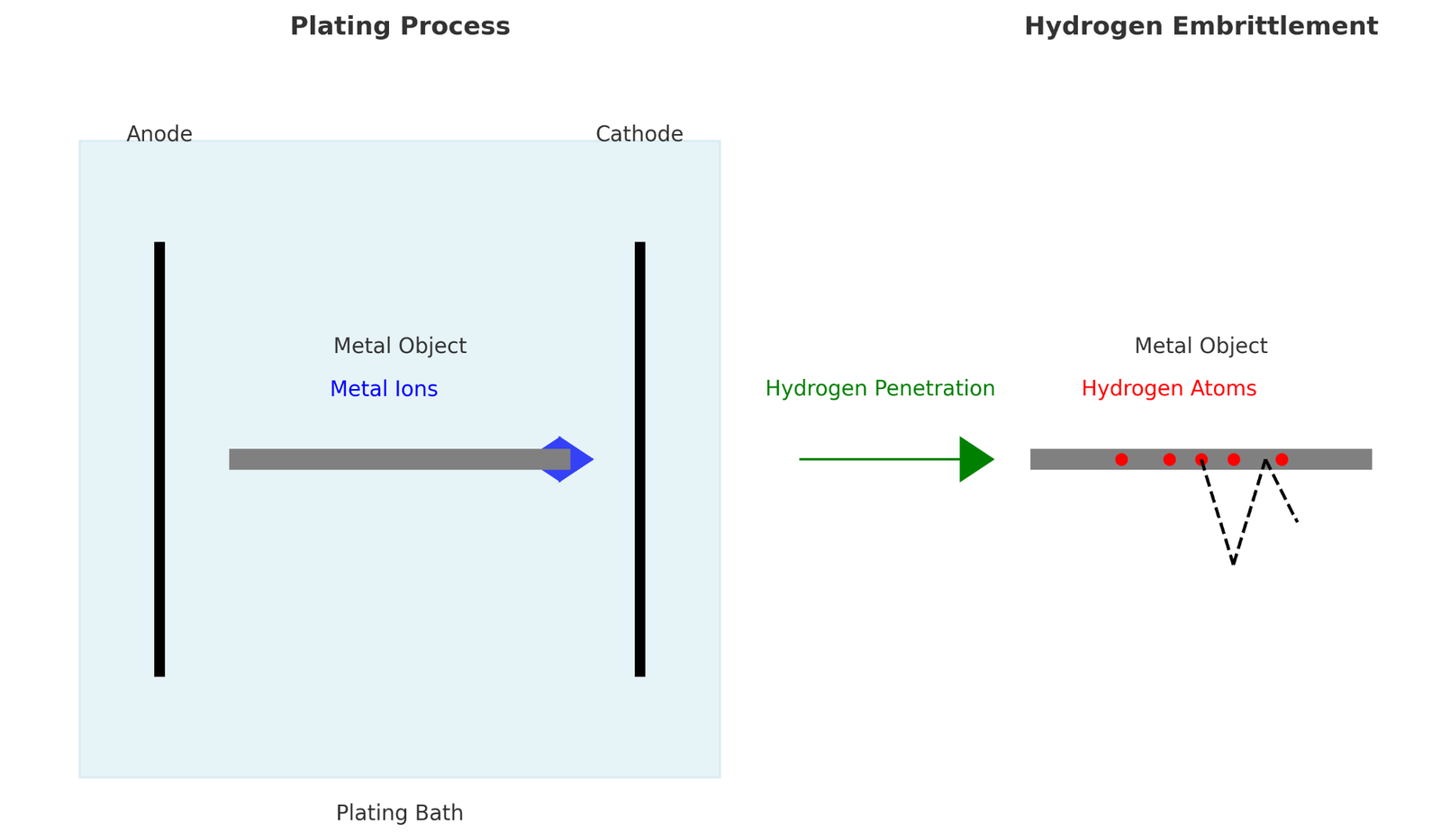

Hydrogen embrittlement (HE) occurs when hydrogen atoms infiltrate a metal’s structure, reducing its ductility and load-bearing capacity. Imagine a mighty steel beam suddenly snapping like a twig – that’s the devastating potential of HE.

This process requires three key ingredients:

- A susceptible material (often high-strength steels, titanium alloys, or aluminum alloys)

- An environment that allows hydrogen to attack

- The presence of stress (either internal or applied)

When two of these factors align, failure becomes not just possible, but inevitable.

The Sneaky Sources of Hydrogen

Hydrogen can be a master of disguise, infiltrating metals through various means:

- Heat treating atmospheres

- Breakdown of organic lubricants

- Steelmaking processes (e.g., electric arc melting of damp scrap)

- Welding with damp electrodes

- High-pressure hydrogen gas environments

- Grinding in wet conditions

- Electrochemical surface treatments (etching, pickling, plating)

Particularly problematic are acid cleaning and high-current electroplating processes, which are incredibly efficient at producing hydrogen.

The Science Behind the Breakdown

Hydrogen embrittlement isn’t a single process, but rather a collection of mechanisms that can lead to metal failure:

- Hydrogen-induced cracking: Hydrogen atoms weaken the bonds between metal atoms, leading to crack initiation and growth.

- Hydrogen-enhanced localized plasticity (HELP): Hydrogen increases dislocation mobility, causing localized deformation and facilitating crack propagation.

- Pressure-induced embrittlement: Hydrogen accumulates at voids or inclusions, increasing internal pressure and leading to micro void coalescence and fracture.

Detection: A Challenging Endeavor

Identifying hydrogen embrittlement, especially at low concentrations, can be like finding a needle in a haystack.

However, some methods have proven effective:

- Simple bend tests to check for ductility loss

- Metallographic techniques to examine near-surface areas and grain boundaries

- Non-destructive testing (NDT) methods like ultrasonic testing and X-ray diffraction

- Hydrogen concentration measurements using thermal desorption spectroscopy (TDS)

Prevention: The Best Medicine

When it comes to hydrogen embrittlement, an ounce of prevention truly is worth a pound of cure. Here are some strategies to keep HE at bay:

- Reduce hydrogen exposure and material susceptibility

- Implement mandatory baking after plating processes

- Utilize test methods to identify susceptible materials

- Opt for lower-strength steels when possible

- Avoid acid cleaning

- Employ low-hydrogen plating techniques

- Minimize residual and applied stress

- Apply surface treatments or coatings to prevent hydrogen ingress

- Perform stress relief heat treatments

The Hydrogen Bake-Out: A Powerful Solution

One particularly effective method for combating hydrogen embrittlement is the hydrogen bake-out process. This involves heating the component to allow hydrogen to diffuse out of the metal. The effectiveness of this method depends on factors like temperature, time, and concentration gradient.

Industry Impact: It’s Not Just Rocket Science

While aerospace applications have seen some of the most severe hydrogen embrittlement issues, it’s crucial to remember that, as one expert put it, “it doesn’t have to fly in order to die.”

HE affects a wide range of industries and components:

- Aerospace: Landing gear components and other critical parts

- Automotive: High-strength steel components used for lightweighting

- Construction: Fasteners and structural elements in bridges and buildings

- Nuclear industry: Various critical components

The Future of Fighting Hydrogen Embrittlement

As we continue to push the boundaries of material strength and performance, understanding and mitigating hydrogen embrittlement becomes increasingly critical. Research into new alloys, improved surface treatments, and advanced detection methods is ongoing.

Conclusion: Vigilance is Key

Hydrogen embrittlement remains a significant challenge in the world of metals. By implementing proper prevention strategies and remaining vigilant, we can reduce the risk of unexpected failures and ensure the integrity of our metal components. Remember, when it comes to hydrogen embrittlement, what you can’t see can hurt you – so stay informed, stay prepared, and keep your metals safe from this invisible threat.

Read More

Boost Profits with Circular Electroplating: How a Circular Economy Lowers Your Variable Costs

Posted By:Venkat Raja

Jul 07, 2024

Tags: