Electronics Manufacturing through Reel to Reel Plating | Advint

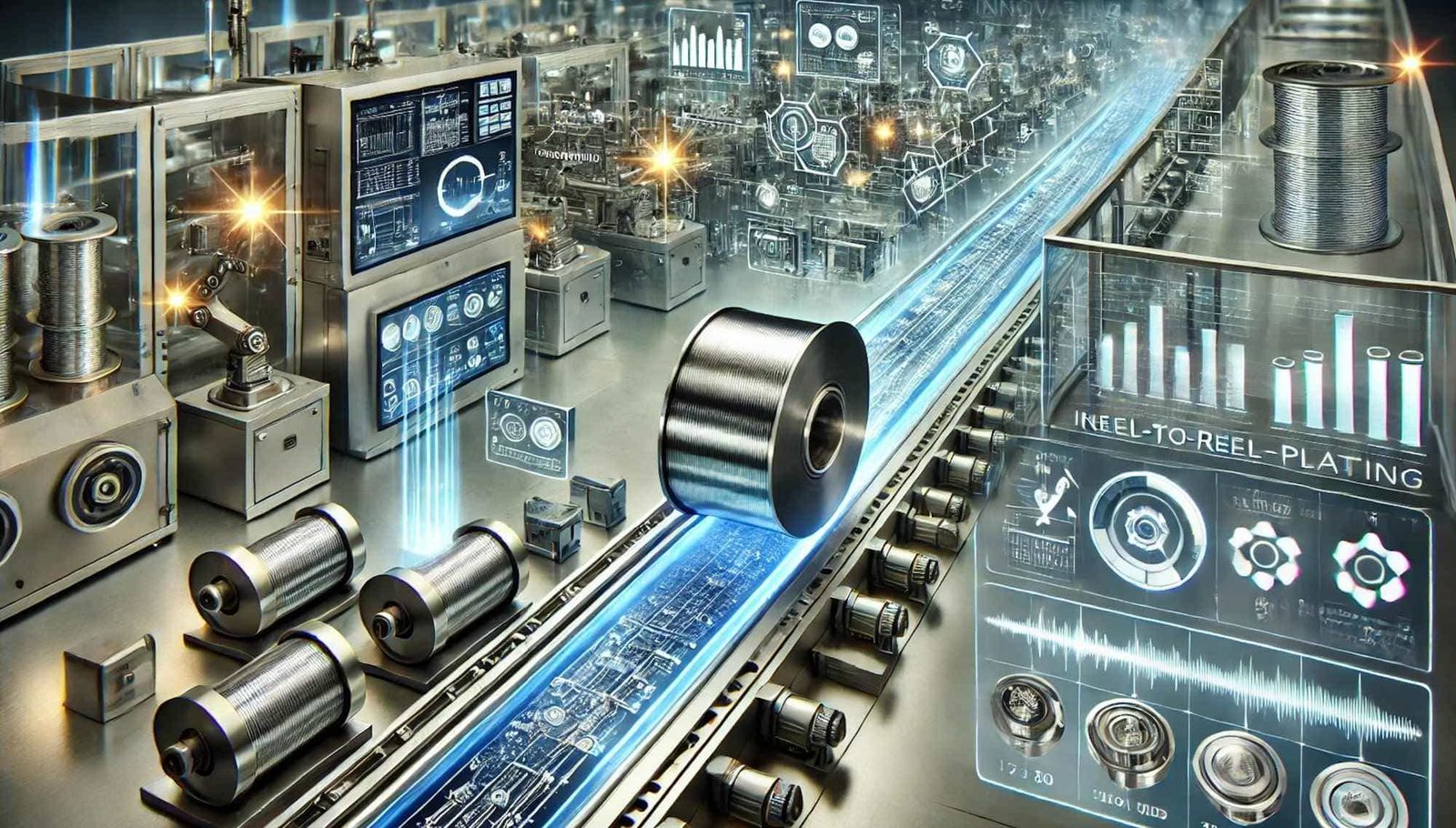

In the fast-paced world of electronics manufacturing, reel-to-reel plating has emerged as a technology that is changing the game. This innovative process combines the time-tested principles of electroplating with cutting-edge automation, resulting in a manufacturing technique that offers unprecedented efficiency, precision, and cost-effectiveness. Reel-to-reel plating is becoming more important as the demand for smaller, complex electronic components increases.

Understanding Electroplating

To fully appreciate the advancements brought by reel-to-reel plating, it’s essential to understand the fundamentals of electroplating. This age-old process involves depositing a thin layer of an element or an alloy onto a substrate through an electrochemical reaction.

The electroplating process typically involves three key steps:

Substrate Preparation: The substrate, often made of metal, undergoes thorough cleaning and preparation to ensure optimal adhesion of the plating layer. This step is crucial for achieving high-quality results and may involve degreasing, acid etching, or other surface treatments.

Electrolysis: The prepared substrate is immersed in an electrolyte solution containing metal ions. A direct current is then applied between the substrate (which acts as the cathode) and a metal electrode (the anode). This electrical current drives the electrochemical reaction.

Metal Deposition: As the current flows, metal ions in the solution migrate toward the cathode (substrate) and are reduced, depositing onto its surface. This process continues until the desired thickness of the metal layer is achieved.

Electroplating is used to enhance various properties of components, such as:

- Electrical conductivity

- Corrosion resistance

- Wear resistance

- Hardness

- Thermal conductivity

- Lubricity and friction

- Solderability

- Aesthetic appearance

While traditional electroplating methods have served industries well, they often face limitations in terms of efficiency, consistency, and control, particularly when dealing with high-volume production of small, intricate components.

Reel-to-Reel Plating

Reel-to-reel plating is a continuous automated process. This innovative approach has transformed the way electronic components are manufactured, offering significant advantages over conventional techniques. In reel-to-reel plating, components are first stamped onto a continuous strip of metal, resembling a film reel. This strip is then fed through a series of plating baths, allowing for precise control over the plating process and enabling high throughput. The continuous nature of the process eliminates many of the inefficiencies associated with batch processing methods.

Key benefits of reel-to-reel plating include:

- Enhanced Efficiency: The continuous flow of components eliminates manual handling and reduces downtime between batches, leading to significantly increased productivity. This streamlined process allows manufacturers to meet high-volume demands more effectively.

- Improved Precision: The controlled movement of the reel through the plating baths ensures consistent and accurate plating across all components. This precision minimizes defects and reduces waste, resulting in higher overall product quality.

- Increased Flexibility: Reel-to-reel plating systems can accommodate a wide range of component shapes and sizes, making them adaptable to various applications. This versatility allows manufacturers to use the same equipment for different product lines, reducing capital investment.

- Cost-Effectiveness: By optimizing material usage, reducing manual labor, and minimizing waste, reel-to-reel plating can significantly lower production costs. The high throughput and improved yield further contribute to cost savings.

- Enhanced Process Control: The continuous nature of reel-to-reel plating allows for real-time monitoring and adjustment of process parameters, ensuring consistent quality throughout the production run. This is achieved using high quality and innovatively designed DC rectifiers with low ripple, optimum voltage and amperage rating.

Selective Plating

One of the most significant advantages of reel-to-reel plating is its ability to perform selective plating. This advanced technique allows for the precise deposition of metal onto specific areas of a component, offering several benefits:

- Reduced material usage, particularly important for precious metals

- Enhanced component performance through targeted plating

- Ability to create complex, multi-functional components

Common selective plating methods in reel-to-reel systems include:

Controlled-Depth Plating: This technique limits plating to a specific depth, ensuring even coverage while minimizing material waste. It’s particularly useful for components that require uniform plating thickness.

Spot Plating: Metal is deposited only in targeted areas, providing localized functionality. This method is ideal for components that require conductive or protective coatings in specific regions.

Strip Plating: A continuous strip of metal is applied across multiple components. This technique is often used in the production of connectors and contacts.

Front and Rear Side Plating: Plating is restricted to two sides of a component, further optimizing material usage. This method is particularly useful for components that only require plating on specific surfaces.

Selective plating enables manufacturers to create complex components with tailored properties, meeting the demanding requirements of modern electronics. Moreover, it contributes to environmental sustainability by reducing the consumption of precious metals and minimizing waste.

Quality Control and Automation

Reel-to-reel plating systems incorporate advanced automation and quality control measures to ensure consistent and reliable results.

These sophisticated systems often include:

- Automated inspection systems that monitor the plating process in real-time

- Advanced sensors that detect defects and ensure compliance with quality standards

- Data collection and analysis capabilities for process optimization

The continuous nature of reel-to-reel plating allows for efficient data collection and analysis, enabling manufacturers to:

- Optimize process parameters using Advint’s Process Development & Control (PDC) tools.

- Identify areas for improvement using Lean concepts

- Ensure traceability and compliance with industry standards such as ISO.

Applications and Future Trends

Reel-to-reel plating has found widespread application across various industries, including:

Electronics: Production of connectors, contacts, and printed circuit boards

Automotive: Manufacturing of sensors, actuators, and electrical components

Medical Devices: Creation of implantable components and diagnostic tools

Aerospace: Fabrication of electrical connectors and structural components

As technology continues to advance, we can expect further innovations in reel-to-reel plating.

Some potential future trends include:

- Nanotechnology Integration: Development of techniques for plating on a nanoscale level, enabling the creation of even more intricate and functional components. This could lead to breakthroughs in areas such as nanoelectronics and advanced sensors.

- Advanced Materials Exploration: Research into new materials for plating, such as alloys and composites, to enhance performance and meet specific requirements. This could result in components with unique properties tailored for specialized applications.

- Industry 4.0 Integration: Incorporation of data analytics, artificial intelligence, and advanced automation to optimize the entire manufacturing process. This could lead to self-optimizing plating systems that adjust parameters in real-time based on production data.

- Sustainable Practices: Development of more environmentally friendly plating processes, including the use of less toxic chemicals and improved recycling methods for plating solutions.

- Additive Manufacturing Integration: Combining reel-to-reel plating with additive manufacturing techniques to create hybrid manufacturing processes, enabling the production of complex, multi-material components.

An Idea in Brief

Reel-to-reel plating represents a significant advancement in electronics manufacturing, offering unparalleled efficiency, precision, and cost-effectiveness. Manufacturers can meet the demanding requirements of modern industries by using electroplating and reel-to-reel automation.

Due to trends like miniaturization, increased functionality, and improved sustainability, reel-to-reel plating is becoming increasingly crucial in the growing electronics industry.

Its ability to deliver precise, selective plating continuously makes it an ideal solution for the challenges of next-generation electronic components.

The future of reel-to-reel plating looks bright, with ongoing research and development promising to unlock even greater capabilities. The maturation and integration of this technology will shape the future of electronics manufacturing. It will enable the creation of innovative products that push the boundaries of what’s possible in our connected world.

Read More

Evaluating the Anodizing Processes of Aluminum and Titanium for Enhanced Material Performance

Posted By:Venkat Raja

Aug 29, 2024

Tags: