Zincate-Free Nickel Electroless Deposition for Microelectronics

Innovation is crucial for progress in the fast-changing realm of microelectronics.

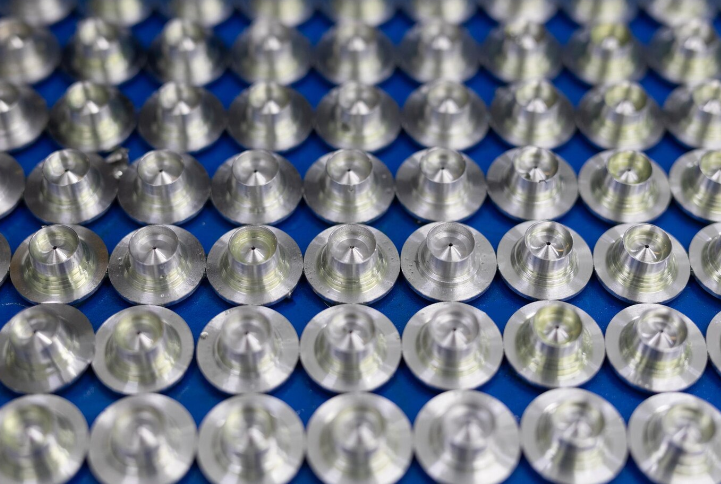

A revolutionary advancement is the zincate-free electroless nickel deposition method on aluminum substrates like rolled, extruded, and foil.

The industry’s critical challenges are being addressed by new approaches that streamline the manufacturing process.

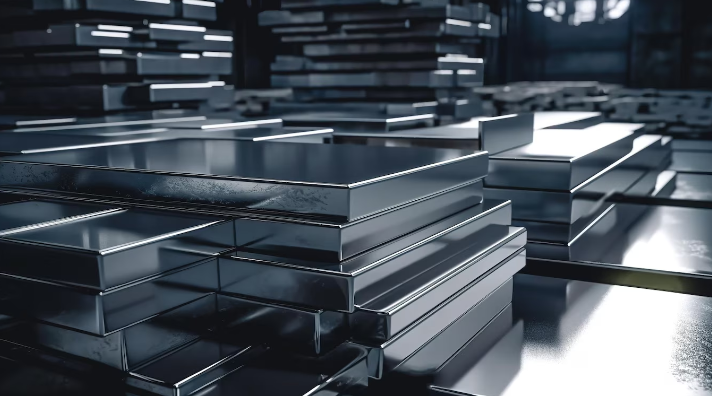

Aluminum has long been the material of choice in microelectronic devices, thanks to its excellent conductivity and cost-effectiveness. However, the formation of an oxide layer on aluminum surfaces presents a significant obstacle for subsequent metal deposition processes. Traditionally, this challenge has been addressed through a multi-step zincate treatment, which involves immersing the aluminum substrate in a concentrated sodium hydroxide solution containing zinc ions.

While effective, the zincate process comes with its own set of drawbacks:

Process complexity

Exposure to undesirable metal ion contaminants

Potential for non-uniform deposition

These limitations have prompted researchers to explore alternative methods for activating aluminum surfaces for electroless nickel deposition. In high-performance microelectronics, the most common metals used for plating include:

Gold:

Excellent conductivity, corrosion resistance, and solderability.

Often used for connectors, contacts, and bonding pads.

Nickel:

Typically used as a barrier layer under gold to prevent diffusion.

Provides good mechanical strength and corrosion resistance.

Silver:

Has the highest electrical and thermal conductivity of all metals.

Used in RF and microwave components, though it tarnishes easily.

Palladium / Palladium-Nickel Alloys:

Provides similar benefits to gold but at a lower cost.

Often used as an alternative to gold for connector finishes.

Copper:

Used as a base layer or interconnect material due to its excellent conductivity.

It is typically plated with a diffusion barrier like nickel before being coated with gold or another finish metal.

Tin:

Used for solderable finishes, often applied over a nickel or copper layer.

Less expensive but prone to whisker formation, which can cause short circuits.

These metals are selected based on their electrical, thermal, and corrosion properties to ensure reliability and performance in demanding microelectronic applications.

Zincate-Free Electroplating

The concept of zincate-free electroplating extends beyond the specific application of electroless nickel deposition on aluminum. It represents a broader trend in advanced surface finishing techniques, particularly for aluminum substrates.

Traditional Zincate Process: Limitations and Challenges

The conventional zincate process, while effective, has several drawbacks:

Adhesion Issues:

- The zincate layer can sometimes result in poor adhesion, leading to peeling or flaking of the plated material.

Environmental Concerns:

- Zincate solutions often contain hazardous chemicals such as cyanide, posing environmental and safety risks.

Time-Intensive:

- The process requires multiple steps, including repeated zincate dips, increasing overall production time.

Several innovative approaches have been developed to overcome these limitations:

Direct Nickel Plating:

- This method uses advanced activation steps to plate nickel directly onto the aluminum surface, often involving etching and surface activation with organic or inorganic chemicals.

Ionic Liquid-Based Plating:

- Environmentally friendly ionic liquids are used as alternatives to traditional plating baths. These liquids can dissolve metals and provide high conductivity, enhancing deposition rates and improving plated layer quality.

Electroless Deposition:

- Some zincate-free methods employ electroless nickel plating, which deposits a thin metal layer without an electric current. This technique offers uniform coating even on complex geometries.

Advantages of Zincate-Free Electroplating

The benefits of zincate-free electroplating extend beyond those specific to electroless nickel deposition:

Enhanced Adhesion:

- By directly plating onto a well-activated surface, the risk of peeling or flaking is significantly reduced.

Environmental Benefits:

- Many zincate-free processes use fewer hazardous chemicals, aligning with the industry’s push for more sustainable manufacturing practices.

Streamlined Processing:

- Elimination of multiple zincate application steps can reduce production times and improve efficiency, particularly beneficial for high-volume applications.

Superior Coating Properties:

- Zincate-free processes often produce coatings with improved hardness, corrosion resistance, and wear resistance compared to traditional methods.

Applications in Modern Manufacturing

The potential applications of zincate-free electroplating techniques extend across various industries:

Automotive:

- Manufacturers are exploring these methods for producing lightweight, corrosion-resistant components, contributing to improved fuel efficiency and durability.

Aerospace:

- The enhanced adhesion and performance of zincate-free coatings make them ideal for aircraft components exposed to extreme environmental conditions.

Electronics:

- In addition to microelectronics applications, these techniques show promise for plating on aluminum heat sinks and connectors, improving thermal management and electrical performance.

Construction:

- Zincate-free plating could enhance the durability and aesthetics of aluminum architectural components.

Conclusion

The advancement of zincate-free electroless nickel deposition for aluminum substrates, along with other zincate-free electroplating techniques, is a breakthrough in microelectronic manufacturing and surface finishing technology. By addressing the limitations of traditional methods, these innovative approaches offer:

- Improved adhesion

- Enhanced performance

- Reduced environmental impact

- Simplified manufacturing processes

These innovations will be essential in shaping the future of technology as the demand for smaller, more reliable, and more complex microelectronic devices increases.

The potential to apply high-quality metal layers to aluminum surfaces without complicated pretreatment offers new opportunities for device design and manufacturing efficiency.

Additional research and optimization are needed before widespread industrial use, but the work of numerous researchers has paved the way. Zincate-free electroless nickel deposition and electroplating will play a crucial role in tackling future challenges in microelectronics and surface finishing.

The pursuit of better manufacturing processes continues, with zincate-free techniques being a major step forward. With ongoing research and exploration, we can anticipate remarkable advancements in advanced surface finishing and microelectronics manufacturing.

You may like also

High Strength, Low Stress Nickel Sulfamate Plating for Aerospace and Automotive Applications

Posted By:Venkat Raja

Sep 29, 2024

Tags: