Anodizing Processes of Aluminum and Titanium | Advint Incorporated

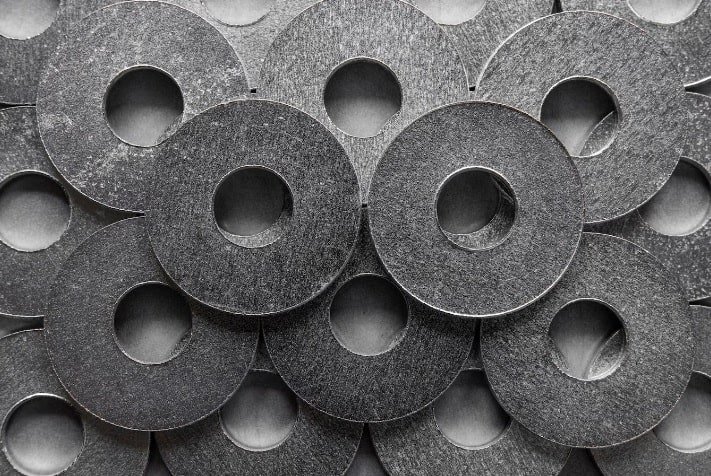

The process of anodizing, which involves forming a protective oxide layer through electrolysis, is extensively used to enhance aluminum and titanium alloys.

This process confers a multitude of benefits, including but not limited to:

- Corrosion resistance: Protects against environmental degradation.

- Wear resistance: Increases material durability and lifespan.

- Aesthetic: Enables a variety of finishes and colors.

- Adhesion: Provides an optimal substrate for subsequent coatings.

While sharing a common underlying principle, the anodizing of aluminum and titanium presents distinct characteristics and applications due to the intrinsic properties of these metals. This comprehensive review delves into the intricacies of anodizing both materials, providing a comparative analysis to inform material selection and process optimization for engineers and manufacturers.

An Overview of Anodizing Process

Anodizing involves immersing a metal in an electrolytic solution and applying an electrical current. This process oxidizes the metal’s surface, creating a porous oxide layer. The thickness and properties of this layer can be controlled by adjusting process parameters, such as voltage, current density, electrolyte composition, and temperature.

For both aluminum and titanium, the anodizing process is initiated by the formation of an initial oxide film that acts as a dielectric. As the voltage increases, oxygen ions migrate through the electrolyte and combine with the metal ions at the metal-oxide interface, leading to the growth of the oxide layer.

Anodizing Aluminum

Aluminum anodizing is a well-established process with a wide range of applications in various industries, including automotive, aerospace, architecture, and consumer goods.

The most common anodizing process for aluminum involves the use of sulfuric acid as the electrolyte. This method produces a hard, durable, and aesthetically pleasing oxide layer.

Sulfuric Acid Anodizing

Process:

Aluminum is immersed in a sulfuric acid electrolyte and subjected to a direct current. The oxygen ions released at the anode react with aluminum to form a porous aluminum oxide layer.

Advantages:

Produces thick, hard, and uniform oxide layers with excellent corrosion resistance and dye receptivity.

Limitations:

Can result in hydrogen embrittlement if not properly controlled.

While sulfuric acid is the most widely used electrolyte for aluminum anodizing, other electrolytes, such as chromic and phosphoric acid, can be employed for specific applications.

Chromic Acid Anodizing:

Produces thinner, more amorphous oxide layers with superior dielectric properties. Primarily used for electronic components.

Phosphoric Acid Anodizing:

Offers improved corrosion resistance and adhesion for subsequent coatings. Commonly used in aerospace and automotive industries.

To enhance the aesthetic appeal of anodized aluminum, dyeing processes can be employed. Dyes penetrate the porous oxide layer, imparting a variety of colors. However, it is essential to seal the anodized layer to prevent dye leaching and improve corrosion resistance. Sealing can be achieved through a boiling water process or by using other sealing solutions.

Anodizing Titanium

Titanium anodizing offers superior performance characteristics compared to aluminum, making it suitable for demanding applications in aerospace, biomedical, and marine industries. The anodizing process for titanium is more complex due to the metal’s inherent properties, such as high oxygen affinity and passive behavior.

Two primary types of titanium oxide coatings are commonly produced: Type I and Type II. Type I coatings focus on improving corrosion resistance and dielectric properties, while Type II coatings enhance lubricity and adhesion for subsequent coatings.

Controlling the thickness of the oxide layer is critical in titanium anodizing to achieve desired performance characteristics. Thicker coatings generally offer better corrosion resistance, while thinner coatings may be preferred for applications requiring improved biocompatibility or lubricity.

Rigorous testing is essential to ensure that titanium oxide coatings meet the specified requirements. Various characterization techniques, including electrochemical impedance spectroscopy, scanning electron microscopy, and X-ray photoelectron spectroscopy, are employed to evaluate the coating’s properties.

A Comparative Analysis

Both aluminum and titanium anodizing aim to create a protective oxide layer. But there are notable distinctions in terms of base metal properties, oxide layer characteristics, process parameters, and applications.

Base metal properties:

Aluminum is softer and more malleable than titanium, which exhibits higher strength and superior corrosion resistance.

Oxide layer characteristics:

Titanium oxide layers are generally harder, thicker, and more corrosion-resistant than aluminum oxide layers.

Process parameters:

Optimal anodizing conditions, including electrolyte composition, voltage, and current density, vary between aluminum and titanium.

Applications:

Aluminum anodizing is widely used in consumer goods and architectural applications, while titanium anodizing is predominantly employed in high-performance industries.

An Idea in Brief

Aluminum and titanium anodizing have unique benefits and are versatile for various uses.

By considering the specific needs of an application, engineers and manufacturers can choose the right metal and anodizing process to enhance material performance.

With the continuous advancement of technology, we anticipate that anodizing techniques will further innovate and open up new possibilities for metals.

You may like also

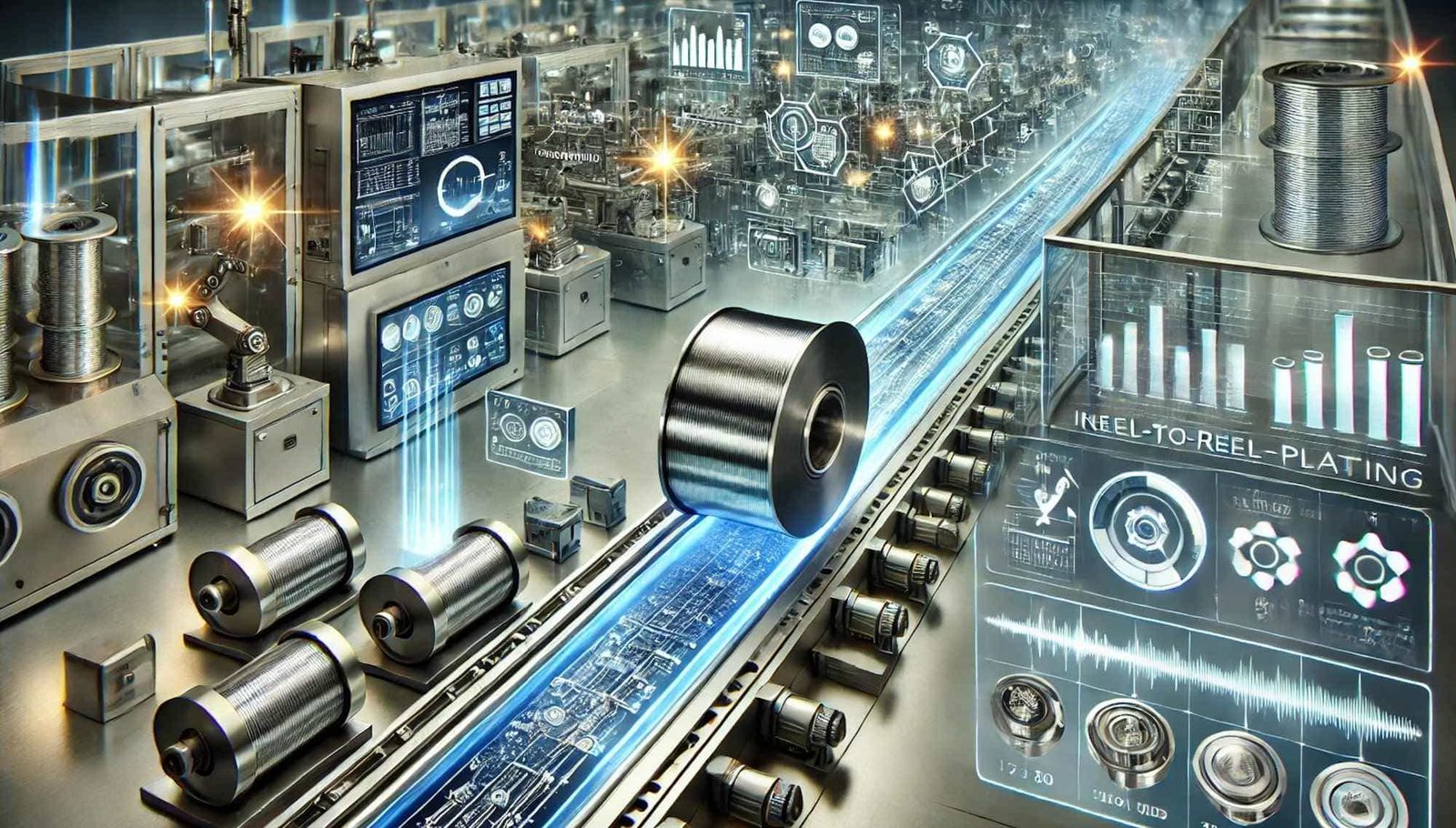

Electronics Manufacturing through Reel to Reel Plating | Advint Incorporated

Posted By:Venkat Raja

Aug 20, 2024

Tags: