How to Use DC Rectifiers to Make a Profound Change in Electroplating

Achieve a profound change in electroplating process control by asking inquisitive questions. Use emotional intelligence with curiosity, be intuitive, lay emphasis on quality over cost, and maximize human and automation potentials.

Who does not want to advance their process performance? If we can improve the process without adding cost it is a windfall, correct? Maximizing automation of power supplies on electroplating, anodizing and electropolishing metal finishing applications is one such method. Automation helps process control. Above automation comes intuitive mind. Intuition is a derived from knowledge and experience. You ought to combine intuition with equipment capability. In this short paper we will review functions, capabilities and advantages of insulated gate bipolar transistor (IGBT) switch mode rectifier and silicon-controlled rectifier (SCR).

Intuition

Einstein nurtured his intuition from his experience of working as a patent clerk while developing his theory of Special Relativity. His presence of mind and theoretical knowledge were instrumental in his brilliant work. Intuition and experience also played a significant role. Likewise, you can use your keen and meticulous observation skills, creativity, innovative mind, knowledge and experience to automate your plating and other metal finishing processes. Managing desires and possessing a non conforming mindset are nuts and bolts to achieve this trait.

Combine this attribute with knowledge in automation and on capabilities such as ampere hour reading and application of current during electrolysis for the finest results. Required capabilities for processes such as anodizing of aluminum, hexavalent or trivalent hard chrome plating, nickel and cadmium plating vary because of electrolytic conditions and electrode potentials.

Automation

Start with questions!

What are the automation opportunities?

Which option makes available the most benefit with less cost and complication?

Automating DC power supply is one of the best choices in an electrolytic process. An excellent choice on a rectifier allows the cathode to receive optimal current. Note, there is a difference between applied and received current. One can read previous articles in this page on current distribution, throwing and covering powers.

A rectifier with RS 485 and 4-20mA analog signal capability and ampere hour (AHR) meter can enable metering of process chemicals during electrolysis. Who doesn’t want consistent output quality? We must reduce variations within input variables to get the desired output quality. Among input variables, there are parameters which vary by electrolysis and others vary primarily because of drag in and drag out of chemicals. It is pertinent to account for both types of variables. Rectifier, PLC and metering system can be programmed ingeniously to realize this aim.

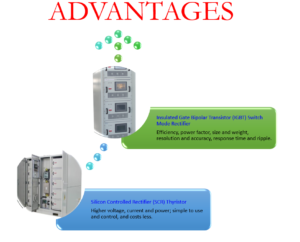

With power supplies, begin by choosing between IGBT switch mode or SCR thyristor DC rectifiers. Ripple factor, unit weight, voltage and amperage accuracy are better with the IGBT rectifier. Ripple is a measure of purity of DC output of a rectifier. Many electrolytic processes, especially precious metals plating like gold and silver plating, are sensitive to a higher ripple percentage. When a SCR rectifier is used at a lower amperage than the rated capacity of a rectifier, ripple is high. Whereas with IGBT rectifiers, ripple factor is consistent and independent of DC output voltage. Digital control allows increased longevity with less maintenance of rectifier and comes with a very high accuracy. When compared with SCR thyristor rectifiers, IGBT power supplies possess higher efficiency and power saving capability.

In a nutshell, by choosing IGBT rectifier you choose better technology, save space and power, improve accuracy resolution and accuracy, and negate the effect of ripple factor. Use of RS485 MODBUS protocol can integrate with programmable logic controller (PLC) and control current, dosing systems and enable trickle current mode at the start of the process.

An Idea in Brief

Achieve a profound change in electroplating process control by asking inquisitive questions. Use emotional intelligence with curiosity, be intuitive, lay emphasis on quality over cost, and maximize human and automation potentials.

We can automate hoist, process sequences, filtration and dosing systems, and rectifiers technologies with this outlook. A splendid choice of DC power supply is important. Both IGBT and SCR rectifiers offer unique advantages depending on the electrolytic process. Aluminum and hydrogen electrolysis, electrowinning and electroforming requirements differ from that of electroplating, anodizing and electropolishing. We recommend considering your process requirements with the capabilities of IGBT and SCR rectifiers.

On precious metals plating, applications distinguish between applied and actual current. Due cognizance can affect the consistency of deposit thickness and the deposit characteristics. When sourcing a rectifier, consider buying from reputed a manufacturer who conducts active research and continuously improves on their design and functionality.

You may like also

Copper Electrowinning: Advanced Rectifier Systems and Power Supplies

Posted By:Venkat Raja

Jan 01, 2020

Tags: