Copper Electrowinning: Advanced Rectifier Systems and Power Supplies

Copper electrowinning is a critical process in the mining and metallurgy industry, essential for producing high-purity copper. This electrochemical method relies on specialized power supplies to extract pure copper from solution. Let’s explore the cutting-edge technologies driving modern copper electrowinning operations, focusing on rectifier systems and power supply solutions that are revolutionizing the industry.

Understanding Copper Electrowinning

Copper electrowinning involves passing an electric current through an electrolyte solution containing dissolved copper ions. This current causes the copper ions to deposit onto cathodes, forming pure copper metal. The efficiency and effectiveness of this process heavily depend on the quality and control of the electrical power supplied.

DC Power Supplies: The Core of Copper Recovery

DC power supplies are the heart of copper electrowinning, converting alternating current (AC) from the grid into the direct current (DC) needed for the process. Key aspects include:

- Precise current density control

- Voltage stability

- Ripple control

- Energy efficiency

These factors directly impact the purity and yield of the recovered copper.

Rectifiers for Copper Electrowinning

DC rectifiers for copper recovery represent a significant advancement in electrowinning technology. These integrated systems combine a transformer and a rectifier in a single unit, offering several advantages:

- Improved efficiency

- Smaller footprint

- Simplified maintenance

- Enhanced control

The evolution of rectifier technology has played a crucial role in enhancing the efficiency and productivity of copper recovery operations worldwide.

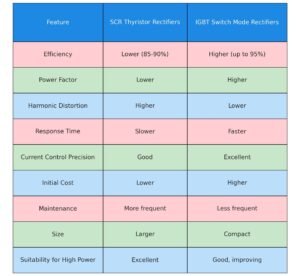

SCR Thyristor Rectifiers in Copper Electrowinning

SCR (Silicon Controlled Rectifier) thyristor-based rectifiers have long been a staple in copper electrowinning power supplies. These robust devices offer:

- High power handling capability

- Reliable operation in harsh industrial environments

- Relatively low cost per kW of power output

- However, SCR thyristor rectifiers have some limitations, including:

- Lower efficiency compared to newer technologies

- Higher harmonic distortion

- Slower response to load changes

Despite these drawbacks, SCR thyristor rectifiers remain widely used in many copper electrowinning facilities due to their proven reliability and cost-effectiveness for high-power applications.

IGBT Switch Mode Rectifiers: The Future of Copper Electrowinning

IGBT (Insulated Gate Bipolar Transistor) switch mode rectifiers are gaining traction in the copper electrowinning industry. These modern power supplies offer several advantages over conventional thyristor-controlled rectifiers:

- Higher energy efficiency (up to 95%)

- Improved power factor

- Reduced harmonic distortion

- More precise current control

- Faster response times

The adoption of IGBT switch mode technology in copper electrowinning rectifier systems is helping mining operations reduce energy costs, improve overall process efficiency, and minimize environmental impact.

Choosing the Right Power Supply for Copper Electrowinning

When selecting power supplies for copper electrowinning, several factors must be considered:

- Current capacity and voltage range

- Efficiency and power factor

- Reliability and maintenance requirements

- Control systems and monitoring capabilities

- Environmental conditions at the site

- Scalability and modularity

- Integration with existing infrastructure

By carefully evaluating these aspects, operators can choose the most suitable rectifier system for their specific copper recovery needs, balancing performance, efficiency, and long-term cost-effectiveness.

Innovations in Copper Electrowinning Rectifier Systems

The field of copper electrowinning is constantly evolving, with ongoing research and development aimed at improving power supply technologies. Recent innovations include:

- Advanced control algorithms

- Internet of Things (IoT) integration

- Hybrid power systems combining SCR and IGBT technologies

- Energy recovery systems

- Smart grid integration

These innovations are pushing the boundaries of what’s possible in copper electrowinning, driving improvements in efficiency, productivity, and sustainability.

Impact of Advanced Rectifier Systems on Copper Production

The adoption of state-of-the-art copper electrowinning rectifier systems has far-reaching implications for the mining and metallurgy industry:

- Increased production capacity

- Improved product quality

- Reduced environmental footprint

- Enhanced operational flexibility

- Long-term cost savings

Comparing SCR Thyristor and IGBT Switch Mode Technologies

Conclusion: The Future of Copper Electrowinning Power Supplies

As global demand for copper continues to grow, driven by industries such as renewable energy and electric vehicles, efficient electrowinning processes become increasingly important. Advanced copper electrowinning rectifier systems, including SCR thyristor and IGBT switch mode technologies, are playing a crucial role in maximizing recovery rates and minimizing energy consumption.

By investing in state-of-the-art power supplies for copper electrowinning, mining operations can improve their productivity, reduce costs, and contribute to more sustainable metal production practices. The ongoing evolution of rectifier technologies promises to further enhance the efficiency and environmental performance of copper electrowinning processes.

As the industry moves forward, collaboration between mining companies, equipment manufacturers, and research institutions will be key to driving innovation in copper electrowinning rectifier systems. By continuing to push the boundaries of what’s possible in power supply technology, we can look forward to a future where copper recovery is not only more efficient but also more sustainable and environmentally responsible.

The choice between SCR thyristor and IGBT switch mode rectifiers will depend on specific project requirements, with a trend towards increased adoption of IGBT technology for its superior efficiency and control capabilities. However, SCR systems are likely to remain relevant, especially in high-power applications where their robustness and cost-effectiveness are valued.

Read More

Ultimately, the future of copper electrowinning lies in optimized power supply solutions that combine the best aspects of various technologies, tailored to meet the unique needs of each operation while maximizing efficiency and minimizing environmental impact.

Posted By:Venkat Raja

Jul 22, 2024

Tags: