The Rise of Cyanide-Free Electroplating: A Sustainable Revolution

The electroplating industry is undergoing a transformative shift, driven by environmental concerns, stricter regulations, and the demand for safer alternatives to traditional cyanide-based processes. Long considered the industry standard for metal finishing, cyanide-based electroplating has faced increasing scrutiny due to its significant risks to human health and the environment. This global movement toward cyanide-free electroplating is more than just a change in chemistry—it represents a sustainable revolution in manufacturing practices. In this article, we explore the advancements in cyanide-free electroplating, the driving forces behind this transition, and its implications for the future of metal finishing.

The electroplating industry is undergoing a transformative shift, driven by environmental concerns, stricter regulations, and the demand for safer alternatives to traditional cyanide-based processes. Long considered the industry standard for metal finishing, cyanide-based electroplating has faced increasing scrutiny due to its significant risks to human health and the environment. This global movement toward cyanide-free electroplating is more than just a change in chemistry—it represents a sustainable revolution in manufacturing practices. In this article, we explore the advancements in cyanide-free electroplating, the driving forces behind this transition, and its implications for the future of metal finishing.

Why Move Beyond Cyanide?

Environmental and Health Risks of Cyanide

Cyanide has been widely used in electroplating due to its effectiveness in facilitating metal deposition.

However, its extreme toxicity poses severe risks:

Human Health Hazards:

Exposure to cyanide can lead to acute poisoning, respiratory issues, and long-term health complications.

Environmental Impact:

Accidental releases of cyanide can contaminate water sources and soil, posing a threat to ecosystems.

Hazardous Waste Generation:

Cyanide-based processes produce toxic byproducts that require extensive treatment and disposal.

Regulatory Pressure

Governments and regulatory bodies worldwide have implemented stringent controls on hazardous substances to mitigate these risks.

Key regulations include:

REACH (Europe):

The Registration, Evaluation, Authorization, and Restriction of Chemicals framework restricts the use of toxic substances like cyanide.

EPA Guidelines (United States):

The Environmental Protection Agency enforces strict measures to limit cyanide usage in industrial processes.

These regulations, combined with growing public awareness of environmental pollution, have accelerated the adoption of safer alternatives.

Innovative Cyanide-Free Electroplating Solutions

Advancements in chemistry have enabled the development of effective cyanide-free electroplating processes across various metals and alloys. Below are some notable innovations:

Zinc and Zinc Alloys

Alkaline Zinc Plating: Utilizing zincate or pyrophosphate electrolytes, these processes offer excellent corrosion resistance and are widely used in automotive parts and hardware manufacturing.

Zinc-Nickel Alloys:

Known for their superior corrosion protection, zinc-nickel combinations are increasingly popular in industries requiring high-performance coatings.

Copper Plating

Alkaline or Acid Electrolytes:

These alternatives to traditional cyanide copper plating deliver comparable performance for applications like printed circuit boards and decorative finishes.

Improved Throwing Power:

Enhanced deposit uniformity makes these solutions ideal for complex geometries.

Precious Metals

Gold Plating:

Sulfite-based electrolytes have replaced cyanide in many gold-plating applications, particularly in electronics and jewelry.

Silver Plating:

Thiosulfate or sulfite-based solutions provide high-quality finishes while eliminating the need for cyanide.

Nickel Plating

Sulfamate and Chloride-Based Solutions: These cyanide-free formulations offer excellent corrosion resistance and are widely adopted across various industries.

Other Metals and Alloys

Research continues into cyanide-free solutions for metals like tin, iron, and copper-tin alloys. Innovations include pyrophosphate-based electrolytes with organic additives for enhanced brightness.

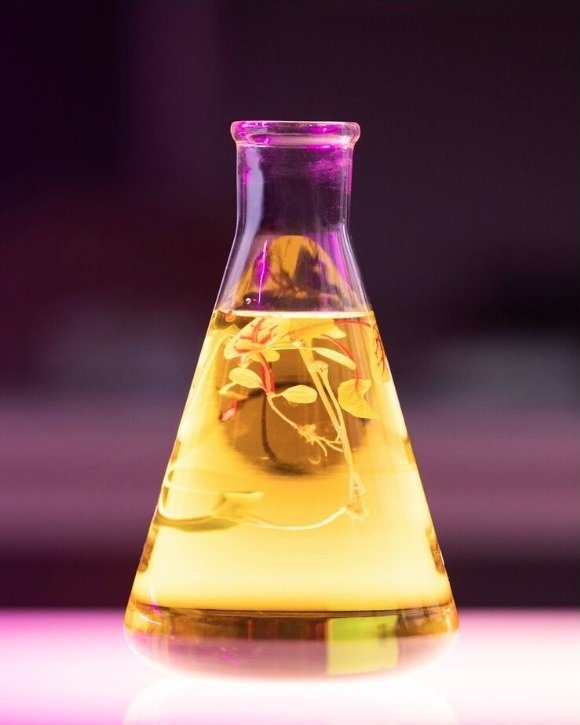

The Science Behind Cyanide-Free Success

The effectiveness of cyanide-free electroplating lies in carefully formulated electrolyte solutions that balance key factors:

-

-

- Metal Ion Sources: Ensure consistent deposition rates.

- Complexing Agents: Maintain solution stability.

- pH Buffers: Optimize process control.

- Specialized Additives: Enhance deposit properties like hardness, ductility, and wear resistance.

-

Modern formulations not only match but often exceed the performance metrics of traditional cyanide-based methods.

Global Leadership in Sustainable Electroplating

Several countries have emerged as leaders in adopting and advancing cyanide-free technologies:

Germany:

Known for its investment in research and development, Germany has set new standards for environmental compliance while maintaining high performance.

Japan:

A pioneer in the electronics sector, Japan has developed cutting-edge solutions for precision applications.

United States:

Collaborative efforts between industry and government agencies have accelerated the adoption of safer technologies.

Business Benefits of Transitioning to Cyanide-Free Processes

The shift to cyanide-free electroplating offers both economic and operational advantages:

-

-

- Economic Benefits

- Reduced waste treatment costs.

- Lower regulatory compliance expenses.

- Decreased insurance premiums.

- Improved market access due to environmental compliance.

- Operational Benefits

- Enhanced worker safety.

- Simplified waste management processes.

- Reduced environmental liability.

- Strengthened corporate reputation as a sustainable manufacturer.

-

Challenges on the Path to Sustainability

While significant progress has been made, challenges remain:

Process Optimization:

Some cyanide-free solutions require further refinement to match the efficiency of traditional methods.

Cost Considerations:

Initial implementation costs can be higher for certain applications.

Education and Training:

Industry personnel need training on new technologies to ensure successful adoption.

Despite these challenges, ongoing research and development continue to improve the viability of cyanide-free alternatives.

Future Horizons in Metal Finishing

The future of sustainable metal finishing is bright, with several exciting developments on the horizon:

Advanced Materials

Researchers are exploring novel alloy combinations that offer multi-functional properties such as enhanced wear resistance or conductivity alongside corrosion protection.

Process Integration

Emerging technologies aim to integrate cyanide-free plating with advanced manufacturing techniques like additive manufacturing (3D printing) for customized applications.

Sustainability Metrics

Industries are adopting comprehensive metrics that evaluate the entire lifecycle of plated products—from raw material sourcing to end-of-life recycling—to ensure sustainability at every stage.

Global Trends Driving Change

The transition to cyanide-free electroplating is a global phenomenon supported by:

-

-

- Stricter environmental regulations worldwide.

- Increased public awareness of health risks associated with toxic chemicals.

- Corporate social responsibility initiatives promoting sustainable practices.

- Countries like China are rapidly transitioning due to strict licensing requirements for cyanide use, while South Korea focuses on cleaner technologies for industrial competitiveness.

-

Early Adoption as a Competitive Advantage

Companies that transition early to cyanide-free technologies stand to gain a competitive edge as global regulations tighten and consumer demand for eco-friendly products grows. Early adopters can position themselves as leaders in sustainable manufacturing while benefiting from reduced operational risks and enhanced market appeal.

Conclusion

The rise of cyanide-free electroplating marks a pivotal moment in the evolution of the metal finishing industry. By embracing innovative chemistries, optimizing processes, and adhering to stringent environmental standards, manufacturers can achieve technical excellence while minimizing their ecological footprint.

For businesses considering this transition, the message is clear: adopting cyanide-free electroplating is not just an environmental responsibility—it’s a strategic imperative.

The technology has matured, the benefits are proven, and global markets increasingly demand sustainable solutions. Those who act now will be well-positioned to thrive in an environmentally conscious manufacturing landscape.

By prioritizing sustainability today, we pave the way for a cleaner, healthier future—one where innovation meets responsibility at every turn.

Posted By:Venkat Raja

Feb 06, 2025

Tags: