Influence of Nickel and Cyanide Ions on Electroplating

The Expertise of Mr. Wood in Cyanide-Based Silver Plating

Donald Wood contributed significantly to the surface finishing industry by inventing (Wood’s) nickel strike formulation around the 1940s. The invention of this formulation and subsequent improvements from the 1960s enabled plating elements of different electromotive force (emf) potential on stainless steel (SS420) and nickel alloys (Inconel) effectively.

Mr. Wood was an expert in cyanide-based silver-plating process and had used silver strike formulation with low free cyanide content.

Mr. Wood was an expert in cyanide-based silver-plating process and had used silver strike formulation with low free cyanide content. In a verbal communication on this subject he had mentioned, “…. a strike solution is generally designed to operate at low cathode efficiency so that a liberal evolution of hydrogen will perform it surface scouring function before metal is deposited”.

Both nickel (cation) and cyanide (anion) ions posses a unique value in plating. We use many elements to develop a strike layer on a substrate, and deposit other elements where electrode potential is different. Gold, copper, iron, and cobalt are a few examples. But most professionals consider the nickel strike deposit the best, and it is most commonly used to form an adherent strike layer. We consider nickel as an element which possesses many refractory properties, though it isn’t a refractory element!

Other than cyanide ions, sulfates, chlorides, and fluoride ions possess good transportation or conducting properties. Plating baths which use simple cyanides (base) for many reasons provide superior physical characteristics than other types of anions.

The point driven above is not about the use of nickel or cyanide. It is about choosing suitable cation and anion(s) in a process at the design phase to achieve sustainable quality.

What is unique about nickel? What is the effect of cyanide in the electrolysis, it can produce exceptions results? What other variables influence quality at the design phase? This blog post introduced a few fundamental electroplating terms. What do they mean? I will answer these questions. Stay tuned for the next post.

You may like also

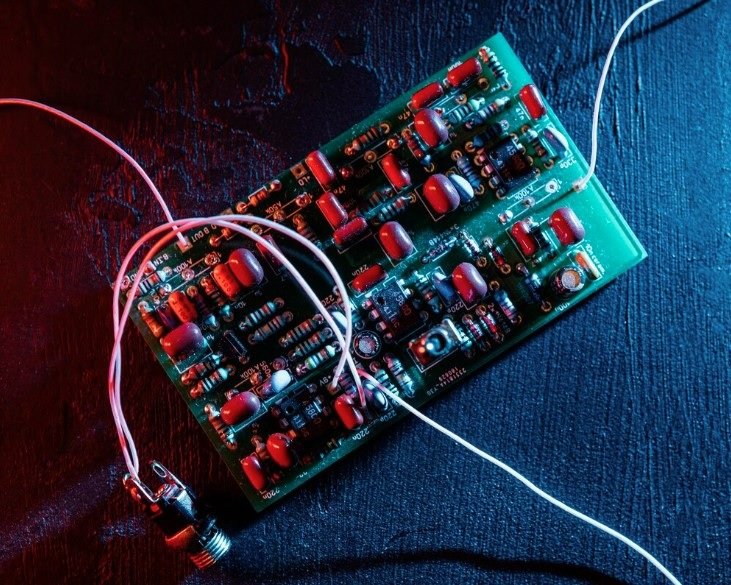

Copper Electrowinning: Advanced Rectifier Systems and Power Supplies

Posted By:Venkat Raja

Feb 06, 2019

Tags: