Contemporary Electroplating Changes

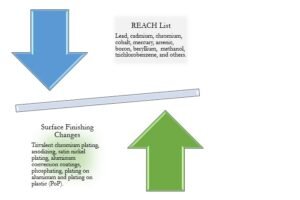

Surface and metal finishing field is going through continuous research and developments driven by REACH and process improvement demand. Some developments and contributions are on trivalent chromium, satin nickel, anodizing, aluminium conversion coatings, plating on aluminium, plating on plastic (PoP), and phosphating. A few proactive applicators focus on automation, process control, use of statistics, and bath purification.

Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) had listed substances of lead, cadmium, chromium, cobalt, mercury, arsenic and solvents such as methanol and trichlorobenzene, and more.

Environmental concerns and market’s competitive spirit have motivated research and creativity. Let us overview the recent progresses with a few examples.

Trivalent Chromium

REACH, RoHS, and other environmental agencies across the globe had listed chromium trioxide (chromic acid) as a hazardous substance. Demand for decorative chromium in automotive sector (plating on plastic) and hard chromium in aerospace sector have forced the drive on trivalent chromium research for over several decades. Various formulations use chloride and sulfate salts of chromium to get the desired deposit properties. Industry had made much progress on advancing decorative chromium and modest improvements on hard chromium.

Anodizing

Boric acid and tartaric acids are replacing chromic acid in aluminum anodizing applications. Type 1 and type 2 anodizing using chromic acid and sulfuric acid contributed gigantically to the industry. Research and applications in boric and tartaric acids are making steady progress in the industry to replace hazardous chromic acid and extremely corrosive sulfuric acid.

Aluminum Conversion Coatings

Lanthanoids and actinoids had offered an interesting array of properties to replace hexavalent and trivalent chromium substances used in the conversion coatings. Other mineral and polymer-based formulations are in development and offered in the industry to meet vast conversion coatings demand of major sectors. Conventionally conversion coatings are an immersion process. Spray conversion coatings are finding unique value with some challenges.

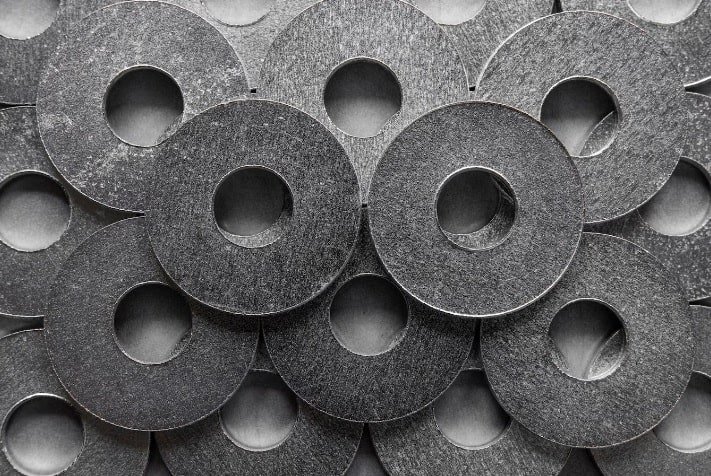

Phosphating

Recent hard work is on to eliminate chromium and nickel from zinc phosphating and other phosphating applications. These newly developed formulations work at lower temperatures than the conventional processes.

Automation

We need to move away from the traditional process improvement methods and be proactive in quality and cost reductions to achieve with ease the true electroplating capability.

Automation is the way to go!

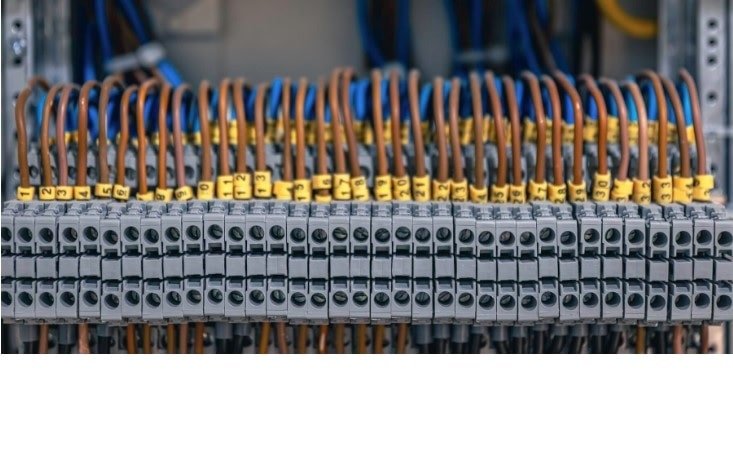

Use automation to control the process parameters such as pH, metal content concentration, uniform current distribution (computational fluid dynamics (CFD)) and focus on creativity with human potential maximization aim. The resultant distribution of the deposit depends on the choice of DC electroplating rectifiers above and beyond other parameters.

An Idea in Brief

We listed a few prominent thematic changes in our field. There are others like elimination of bioaccumulate perfluoro octane sulfonate (PFOS) and identification of boric acid alternatives on Watts nickel plating and acid chloride zinc plating applications.

While the listed developments are interesting and credible, we advise the process owner not be credulous when choosing a new formulation or a process. On some cases, the developments are significant and on some there are gaps in the meeting of required deposit physical characteristics. We recommend a process owner to acquaint with the salesman’s enthusiasm and a researcher’s curiosity, consequential in being carried by advantages and not projecting a balance of pros and cons!

Advint’s advisory services help clients on the best choice of processes, DC rectifiers and automation.

You may like also

Pulse Aluminum Anodizing for Energy Efficiency | Advint Incorporated

Posted By:Venkat Raja

Sep 01, 2020

Tags: