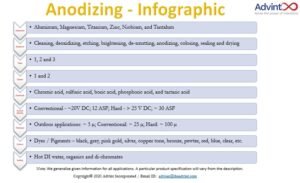

Aluminum Anodizing: A Simple Pictographic Synopsis

Anodization is an electrolytic oxidation process where a substrate is anodic and the process forms a thick oxidized layer. We commonly refer to anodizing and chemical conversion coatings as light metal finishing. Aluminium, because of electromotive force (emf) series and emf potential, is a thermodynamically reactive metal and the most frequently anodized metal. We can anodize other metal alloys and there are several types and classes of anodization. In this short paper, let us look at the basics of anodization with specifics and a visual.

Anodized Metals

Other than aluminum, we can anodize magnesium, titanium, zinc and tantalum.

Applications

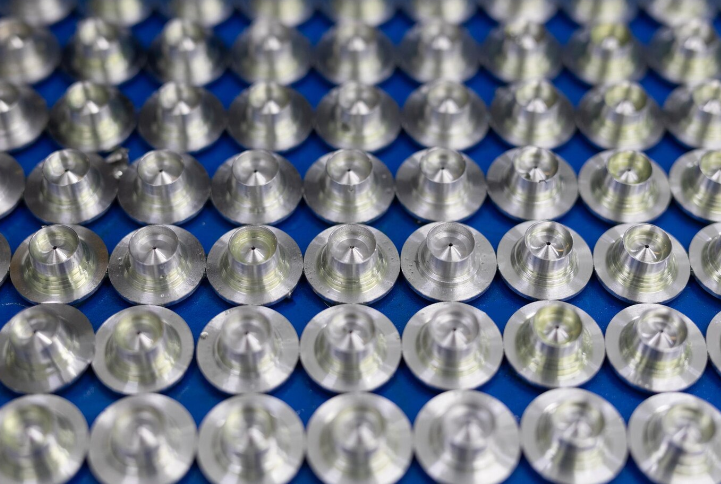

Anodization is a low cost and low maintenance application. Sectors such as aerospace, space, hardware and automotive industries, cookware, and mobile devices like cell phone use this process.

Types and Classes

Anodization possess good covering power, excellent adhesion, and is hard and scratch resistant. It finds applications on outdoor, architectural, and as a hard coat on engineering purposes. It is used to improve adhesion before painting. Aluminium and other refractory metals possess natural barrier layers, but anodized thickness layer is much thicker.

There are three types – 1, 2 and 3 and two classes – 1 and 2. The chemicals and thickness distinguish the type and class, and they are specific to applications.

We regularly use sulphuric acid on type 2 on both conventional and hard aluminum anodizing applications. Chromic acid, boric acid, and tartaric acid are used for Al anodization. Tartaric acid is one of the most environmentally friendly acids, whereas REACH and alike agencies identify chromic acid and boric acid (potential) as hazardous. Boric Sulfuric Acid Anodizing (BSAA) and Tartaric Sulphuric acid Anodising (TSA) are replacing chromic acid for the aforesaid cause. We can seal the anodized layers. Aluminum anodized resists chemicals between 4 and 8.5 pH, and they are good insulators.

Note: There are proprietary and non proprietary anodizing formulations available in the market.

Colours

Industry offers several colours of anodized layers like black, grey, pink gold, silver, copper tone, bronze, pewter, red, blue, clear and a few others. Dyes or pigments are used to colour the anodized layers before sealing and drying. Note, colouring and sealing are optional and on many applications are not preferred.

Processing Sequences

Cleaning, deoxidizing, etching, brightening, de-smutting, anodizing, colouring (dyes or pigments), sealing (DI water, organics and di-chromates) and drying.

Anodized Layer Thickness

The thickness of conventional anodizing layer range between 17 and 30 microns. Chromic acid anodizing and anodizing done on outdoor applications have much lesser thickness range – ~ 5µ. Thickness of hard aluminum anodized layer are ~ 4 mils.

Current Density

We can conduct conventional anodization at 12 ASF (~18 – 24V), between 10 and 60 minutes at 70ºF electrolyte temperature. We can conduct hard anodizing at 25 V, and between 24 and 36 ASF.

Summary

This paper gives a simple outline of anodizing process for novices in the industry. Use the infographic to get quick information on the process and at a later month Advint will write an elaborate paper on this subject for forward-thinking users.

You may like also

Hydrogen Embrittlement: The Hidden Danger Compromising Metal Strength

Posted By:Venkat Raja

Aug 01, 2020

Tags: