Advint presents the most comprehensive, cost-efficient, online electroplating industry training and is the fastest growing services in the global field. We adapt this industrialized education for research, engineering, and manufacturing staff, and attendants acknowledge as a gold standard. Regardless of prior acquaintance, one will discover the study intuitive and have several outcomes to practice at work. This course covers REACH compliant and latest deposition techniques, including trivalent hard and decorative chromium plating, and plating with cyanide-free precious metal formulas.

As we prepare to unveil an extensive array of 450 meticulously crafted PowerPoint slides, Advint stands as your unrivaled partner in meeting all your training requirements.

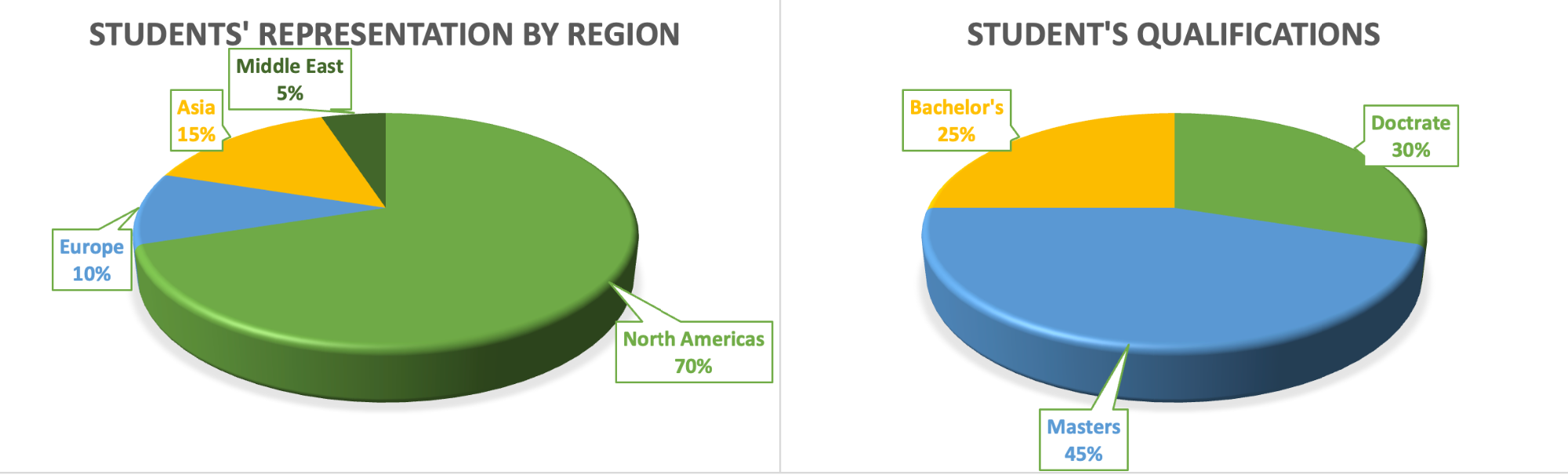

Our esteemed clientele, hailing from the USA, Europe, the Middle East, and Asia, attest to the unparalleled quality and efficacy of our services.

Principal scientists, process engineers, leaders in continuous improvement, supply chain, and operations, alongside executives from prominent corporations, have entrusted Advint with their professional development journey and emerged wholly satisfied.

Scroll down and immerse yourself in a selection of testimonials, echoing the success stories of those who have journeyed with us.

Course Summary

|

Prerequisites

|

Unique Value

|

Content |

Learning |

Value |

|---|---|---|

Electrochemistry - Basics |

|

The module will cover the fundamentals of chemistry. It will simplify the most important electrochemical concepts of industrial electrolysis. |

Electroplating - Concepts |

|

You will learn important electroplating mechanisms. Learn real life accessories required to master practical deposition and coating applications. |

Analyzes—Electrolyte & Deposit |

|

This module will cover the highlights of several electrolytes and deposit testing techniques. |

Applications—Electrolytic, Electroless & Immersion |

|

This module builds on the previous learning and deals with the specifics of a process, formulation, control and maintenance. |

Process Development & Control Methods |

|

Planning, organizing, decision making, and control are important for an organization to create a surplus. This module helps leverage the learning from other modules and maximizes effectiveness. |

Session 1

|

Session 2

|

||||||||||||||||||||||||||||

"The class was very informative and covers in-depth technical concepts. Venkat has made the concepts easy to understand. Would recommend this course for practitioners in electroplating." - Sudhakar K.

"The online electroplating training is a intense course that covers all aspects of industrial electroplating starting with the basics of chemistry through to implementation of quality management methods. Venkat clearly depicts the necessity and the benefits of understanding all your process parameters. His calm and patient attitude gives the student enough time to grasp all the information and for further development he can provide additional literature too." - Finn D.

"The electroplating training course by Advint is an excellent course if one wants to learn strong electroplating fundamentals and process design. Venkat Raja custom structured the course for me to choose areas where I wanted to focus. I was able to go from knowing every less to a good fundamental knowledge in the 4 day course. Totally recommend." — Dr. Manmohan L.

"I am so glad I took this course. Venkat was able to refresh my (very rusty) memory on chemistry fundamentals, taught me much about electroplating and enlightened me on design considerations for new process as well as easy to implement plans to improve any process.

The time spent and the E-book are invaluable. I not only feel like I gained knowledge but also the ability to apply and implement improvements. Venkat also ensured questions were asked that we may take with us to further enhance our understanding of any issue that arises-paving the way for our successful future expert selves.

I would also like to add that Venkat was very dyanmic in his ability to tailer content to the student 'on the fly' with his excellent listening skills and ability to distill complex theories into manageable pieces." — Dara W.

"Excellent class experience. The topics included critical review of fundamentals but also allowed for interactive time to evaluate work applications." — Tony P.

"I took Advint's 4-day intensive on electroplating and left the course having learned more than I have working in electroplating R&D for 7 years. The course was a perfect balance of deep fundamentals and high-level process control. I highly recommend this course for anyone in the metal finishing field if they want to improve the quality and consistency of their coatings. Amazing!" — Luke S.

"This is exactly what I needed and what most people would benefit from in my opinion, the type of information given is simplified yet condensed, covering everything from the basics to the technology, implementation, and managerial aspects. The interactive course really helped with the flow of information between each other. Many thanks to the organizer, it was awesome!" — Ralph K.

"This is to thank you and Advint for offering a very comprehensive industrial electroplating course. The training that I received under your guidance would definitely prove to be beneficial in my future career and the journey ahead. The course not only covers the technical aspects of electroplating, but also teaches the students and early professionals the business development methodology and to get the most out of the resources in hand. The concepts of electrochemistry were very well explained. Talking about the electroplating field, everything from A to Z was well explained. The knowledge and experience of Mr. Venkat would benefit each and every individual to delve deeper into the subject. Moreover, his patience and calmness was something remarkable. From the beginning of the course, the candidates have the sense of freedom to freely and openly ask questions. The E-Book is something which each and every person in this field would want to read in order to achieve a better understanding of the subject. A very intensive book, which I would benefit from throughout my career. In the end, I would say that I am glad that I could start my journey in this vast industry under the leadership and mentorship of Mr. Venkat." — Kartik J.

"The course is designed with very specific tools and techniques for making the job in electroplating industry to be understood easily.

You need a very basic knowledge of chemistry before understanding the concepts dealt in the course.

The topics have been covered in enough depth and length to show a way to look for opportunities in the existing process." — Kumar A.

Advint takes a comprehensive approach to designing custom electroplating training programs tailored to the unique needs of corporate teams across various industries. By following a structured process, we ensure the course is effective, relevant, and aligned with industry best practices.

The journey begins with a thorough needs assessment, where Advint gains an in-depth understanding of each industry's specific requirements and challenges. Click questionnaire link for additional information. We identify knowledge gaps, skill levels, and desired outcomes, enabling particpants to develop custom curricula that address the unique needs of aerospace, automotive, and electronics sectors.

The tailored training content covers industry-specific regulations, REACH or EPA requirements, material compatibility, surface finish requirements, and quality control standards, ensuring participants receive comprehensive and applicable knowledge.

Advint's training programs go beyond theoretical concepts by incorporating practical, hands-on exercises that reinforce learning. Participants have the opportunity to work with actual electroplating equipment and materials commonly used in their facilities, fostering a deeper understanding of real-world applications.

Safety is a paramount concern in electroplating processes, and Advint places a strong emphasis on safety protocols and best practices. Training modules cover handling hazardous materials, chemical abstract service (CAS) numbers, personal protective equipment (PPE), and emergency procedures, equipping participants with the knowledge to mitigate risks effectively.

For experienced engineers, Advint offers advanced training modules that delve into topics such as process optimization and innovative electroplating technologies. These modules empower participants to stay ahead of the curve and continuously improve their skills.

Additionally, Advint provides certificates that validate participants' skills and knowledge in electroplating processes. These certifications enhance their credentials and career prospects within their respective industries.

Advint understands the importance of staying current with industry developments and emerging trends. They regularly update and refine their training materials based on participant feedback and technological advancements, ensuring the course content remains relevant and cutting-edge.

To accommodate the diverse needs and preferences of corporate teams, Advint offers flexible delivery options, including in-person workshops, online courses, and blended learning approaches, allowing participants to choose the format that best suits their learning style and schedule.

Advint collaborates with industry organizations, professional associations, and subject matter experts to enhance the credibility and relevance of their training programs. These partnerships ensure that the courses align with industry standards and best practices, providing participants with a comprehensive and authoritative learning experience.

By following this comprehensive approach, Advint designs electroplating training courses that empower corporate teams in aerospace, automotive, electronics, and line operators to develop the necessary skills, knowledge, and expertise to excel in their respective industries.

Seize this chance to explore tailored solutions perfectly aligned with your needs. Simply complete the brief questionnaire below, and our dedicated team will promptly reach out with a proposal or quote crafted just for you. Don't hesitate - contact us via email or phone, and let's embark on a journey towards realizing your vision together.

|

|

|